Look around you. Whether you're reading this on your smartphone, glancing at your laptop monitor, or checking the time on your smartwatch, there's a very high chance you're looking at a TFT LCD display. This technology is the workhorse behind the visual interface of countless modern devices. But what exactly is a TFT LCD, and how does it create the bright, colorful images we see every day? Let's dive in and demystify this engineering marvel.

What is a TFT LCD?

First, let's break down the acronym:

LCD (Liquid Crystal Display): An LCD is a flat-panel display that uses the light-modulating properties of liquid crystals. These crystals don't produce their own light; instead, they rely on a backlight and act like tiny shutters to either block or allow light to pass through.

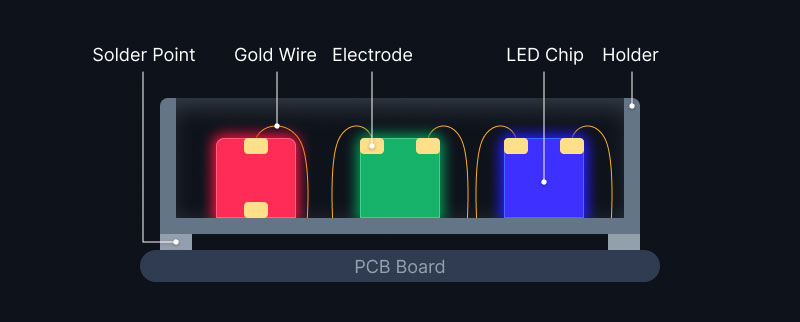

TFT (Thin-Film Transistor): This is the active matrix technology that drives the LCD. A TFT is a special type of transistor made from a thin film of semiconductor material deposited on a glass panel. For every single pixel on the screen, there are one or more of these tiny transistors.

So, a TFT LCD is essentially an active matrix LCD where each pixel is controlled by one to four transistors. This setup allows for faster response times, sharper images, higher contrast, and better color reproduction compared to older, passive matrix LCDs. It's the "smart" and precise way to control an LCD.

How Does a TFT LCD Work?

The magic of a TFT LCD lies in its layered structure and precise control of light. Here’s a step-by-step breakdown:

1. The Backlight:

The process starts with a bright white LED backlight at the rear of the display assembly. This light source is always on, providing the illumination for the entire screen.

2. The Polarizers:

The light first passes through a polarizing filter. This filter only allows light waves vibrating in a specific direction to pass through, creating polarized light.

3. The Liquid Crystal Layer:

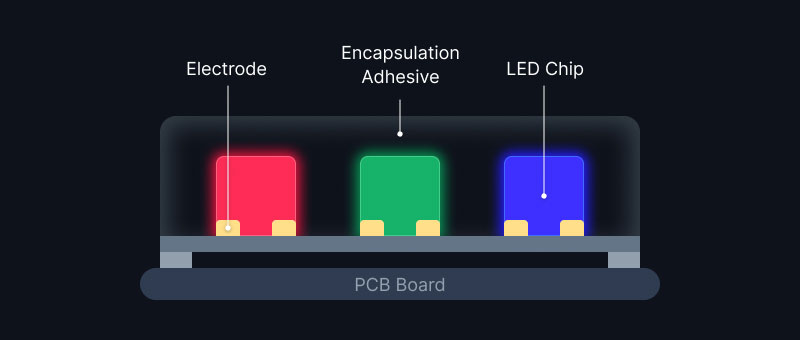

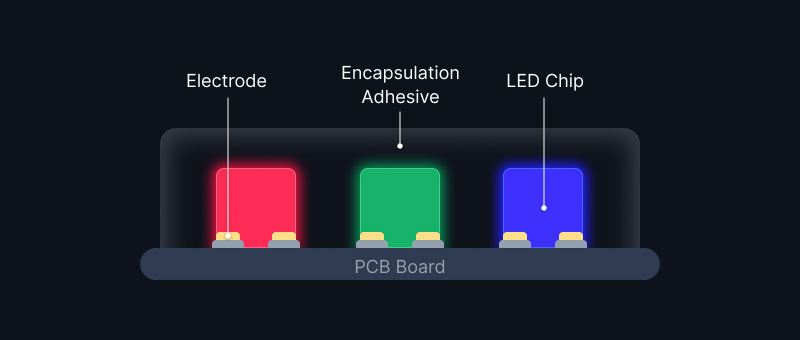

This polarized light then reaches the layer of liquid crystals. Each pixel is made up of three sub-pixels—red, green, and blue (RGB)—each with its own transistor. By applying a precise electrical voltage via the TFT, the twist of the liquid crystals changes. This twisting action either twists the polarized light to allow it through or untwists to block it, acting like a microscopic shutter for each sub-pixel.

4. The Color Filter:

After passing through the liquid crystal layer, the light hits a color filter. This filter has individual red, green, and blue segments for each sub-pixel. The amount of light that passed through each sub-pixel now shines through its corresponding color filter, creating the exact shade of red, green, or blue needed.

5. The Second Polarizer:

Finally, the light passes through a second polarizing filter. This filter is oriented at a 90-degree angle to the first one. Its job is to analyze the light that has been altered by the liquid crystals. The combination of these two filters and the liquid crystals' twisting action ultimately determines whether light is allowed to pass through for that pixel or not.

Your brain blends the intense of these millions of tiny red, green, and blue sub-pixels together to perceive a single, full-color pixel. Millions of these pixels working together form the complete image on your screen.

Key Advantages of TFT LCDs

High Contrast & Image Quality: Offers sharp and vibrant images.

Cost-Effective: Mature manufacturing processes make them relatively inexpensive to produce.

Long Lifespan: LEDs have a very long operational life.

Reliability: Solid-state technology with no moving parts.

Conclusion

TFT LCD technology is a masterpiece of engineering that combines the precise control of thin-film transistors with the unique light-modulating properties of liquid crystals. From your phone to your TV and the dashboard in your car, this reliable, efficient, and cost-effective technology continues to be a dominant force in bringing digital information to life right before our eyes. Gvlcd is a professional TFT LCD display manufacturer,get more details from us quickly!