Project Background

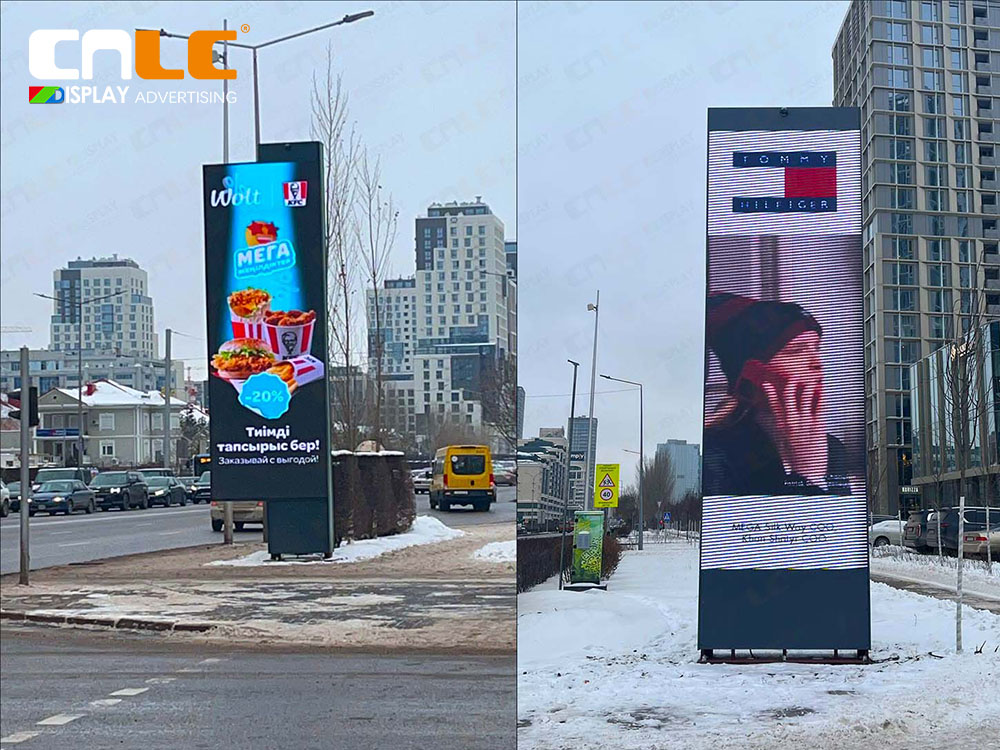

In 2023, CNLC successfully launched a large-scale outdoor LED billboard project across several cities in Central Asia, collaborating with leading DOOH media companies. This strategic partnership allowed CNLC to deploy 50+ high-performance LED displays, including multiple models and sizes, to meet diverse advertising needs for urban branding, commercial campaigns, and public messaging.

Over the past two years, CNLC’s outdoor digital signage solutions have proven highly reliable, demonstrating outstanding performance under the region’s challenging climate conditions.

Project Details

For this project, CNLC deployed three core products:

-

4×3m P4 High-Resolution LED Billboard

-

7.5×1.92m Outdoor LED Billboard

-

Fixed Large LED Screen

All displays feature aluminum structure designs, offering lightweight, corrosion-resistant, and durable performance ideal for outdoor environments. The high-brightness LED displays (up to 5500 nits) ensure excellent visibility even in direct sunlight, while intelligent cooling and temperature control systems maintain stable operation and prolong lifespan.

The screens also support remote management and smart control, allowing media operators to update content, monitor performance, and perform maintenance efficiently, reducing operational costs while improving advertising impact.

Performance After Two Years

After two years of continuous operation, these outdoor LED billboards have maintained high reliability and consistent performance:

-

✅ All-weather operation: Reliable under extreme heat, freezing temperatures, heavy rain, and dust storms.

-

✅ Effective advertising: Used by media companies for brand promotion, commercial campaigns, and city information, maximizing audience engagement.

-

✅ Positive feedback: Easy maintenance, stable content display, and high ROI for advertising partners.

These results highlight CNLC’s commitment to delivering durable and high-quality outdoor digital signage solutions.

Key Advantages of CNLC Outdoor LED Billboards

-

Durable Aluminum Structure

The aluminum body provides strength, corrosion resistance, and lightweight durability — a key factor for long-term outdoor use. -

Multiple Models for Diverse Applications

From 4×3m high-resolution LED billboards to 7.5×1.92m outdoor LED billboards and large fixed screens, CNLC covers a wide range of DOOH applications. -

High-Brightness, Energy-Efficient Displays

5500 nits high-brightness LED displays ensure clear visibility day and night, while intelligent cooling optimizes energy efficiency. -

Smart Remote Control and Easy Maintenance

Centralized remote management enables media operators to efficiently control content, monitor performance, and maintain screens with minimal effort.

Project Significance

This project demonstrates CNLC’s expertise in delivering outdoor digital signage solutions in Central Asia:

-

For media companies: Efficient, reliable LED billboard systems that enhance advertising reach and ROI.

-

For cities: Modern, high-visibility digital signage that enhances urban branding and public messaging.

-

For CNLC: Proof of long-term reliability across multiple cities and challenging climates, creating a reference for future international projects.

Conclusion

The CNLC 2023 outdoor LED billboard project in Central Asia has successfully operated for two years, showcasing high performance, durability, and reliability. With aluminum-structured LED billboards, multiple models, and smart management systems, CNLC continues to provide trustworthy and efficient DOOH solutions for media partners and cities worldwide.

👉 Learn more about CNLC outdoor LED billboard and digital signage solutions: www.cnlcdisplay.com