In modern mobile communication networks, especially during the deployment of 4G LTE and 5G NR, the number of frequency bands and systems continues to increase. To reduce the complexity of the antenna-feeder system and improve network deployment efficiency, the combiner has become an essential passive component in both macro base stations (macro sites) and Distributed Antenna Systems (DAS). Proper use of combiners not only reduces CAPEX and OPEX but also optimizes network performance, making them a key part of RF system design.

Applications of Combiners in Macro Sites

Macro base stations often face the need for multi-standard and multi-band signal co-deployment, such as 700 MHz, 1800 MHz, 2100 MHz, and 2600 MHz operating simultaneously. If each frequency band used a separate antenna-feeder system, it would lead to tower space congestion, excessive feeder lines, and higher maintenance costs.

Typical Applications:

-

Multi-band Combining

Multiple frequency bands are combined via a combiner and transmitted through the same feeder cable to the antenna port, significantly reducing feeder count. -

Site Sharing

In limited site locations, signals from different operators can share a common antenna system through combiners. -

Tower Load Reduction

Combiners reduce the number of antennas and feeders on towers, decreasing structural load and improving site safety.

Advantages:

-

Lower CAPEX (equipment and installation costs)

-

Reduced OPEX (maintenance and energy costs)

-

Improved structural reliability of towers

-

High signal isolation to avoid intermodulation interference

Applications of Combiners in DAS

DAS is widely used in large venues, shopping malls, subways, and airports where high-capacity indoor coverage is required. Unlike macro sites, DAS must support multi-band and multi-operator signals indoors, and combiners play a critical role in achieving this.

Typical Applications:

-

Multi-technology Coverage

Signals from GSM, WCDMA, LTE, and 5G NR are combined and distributed into the indoor antenna system. -

Multi-operator Sharing

Signals from different operators are combined via combiners to share the same DAS, avoiding redundant construction. -

Multi-floor Coverage

In high-rise buildings, combiners are used to merge or distribute signals across multiple floors and frequency bands.

Advantages:

-

Reduced cabling and space savings in equipment rooms and conduits

-

Lower Passive Intermodulation (PIM) levels, ensuring better signal quality

-

Greater system flexibility and scalability

Combiner Selection and Performance Optimization

-

Low PIM Performance

LTE and 5G systems are highly sensitive to PIM. Low-PIM combiners significantly improve network capacity and user experience. -

Wideband Compatibility

Combiners should support multiple frequency bands simultaneously and allow for future expansion into new bands. -

Insertion Loss Control

Lower insertion loss ensures higher transmission efficiency. A balance must be achieved among bandwidth, isolation, and insertion loss. -

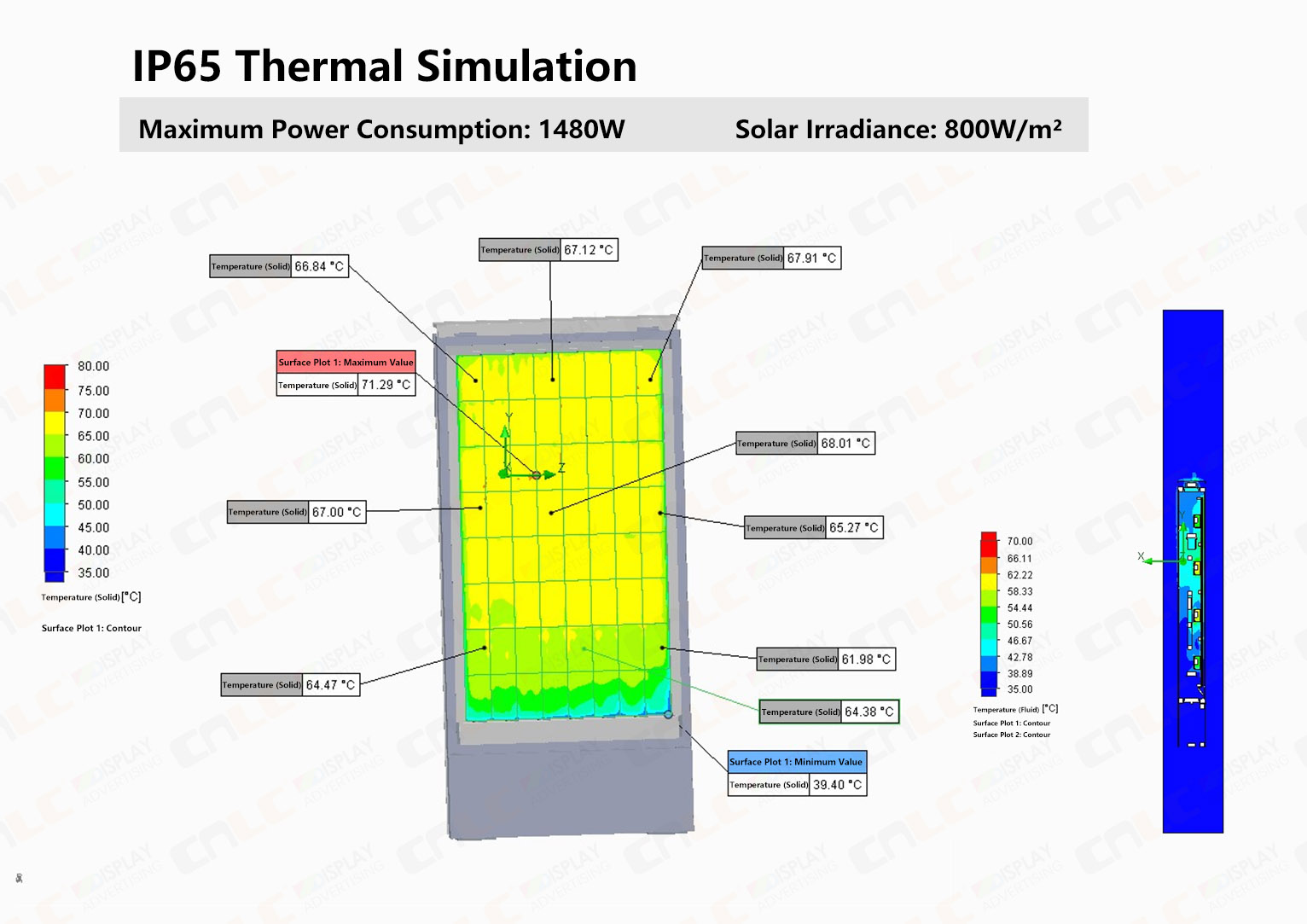

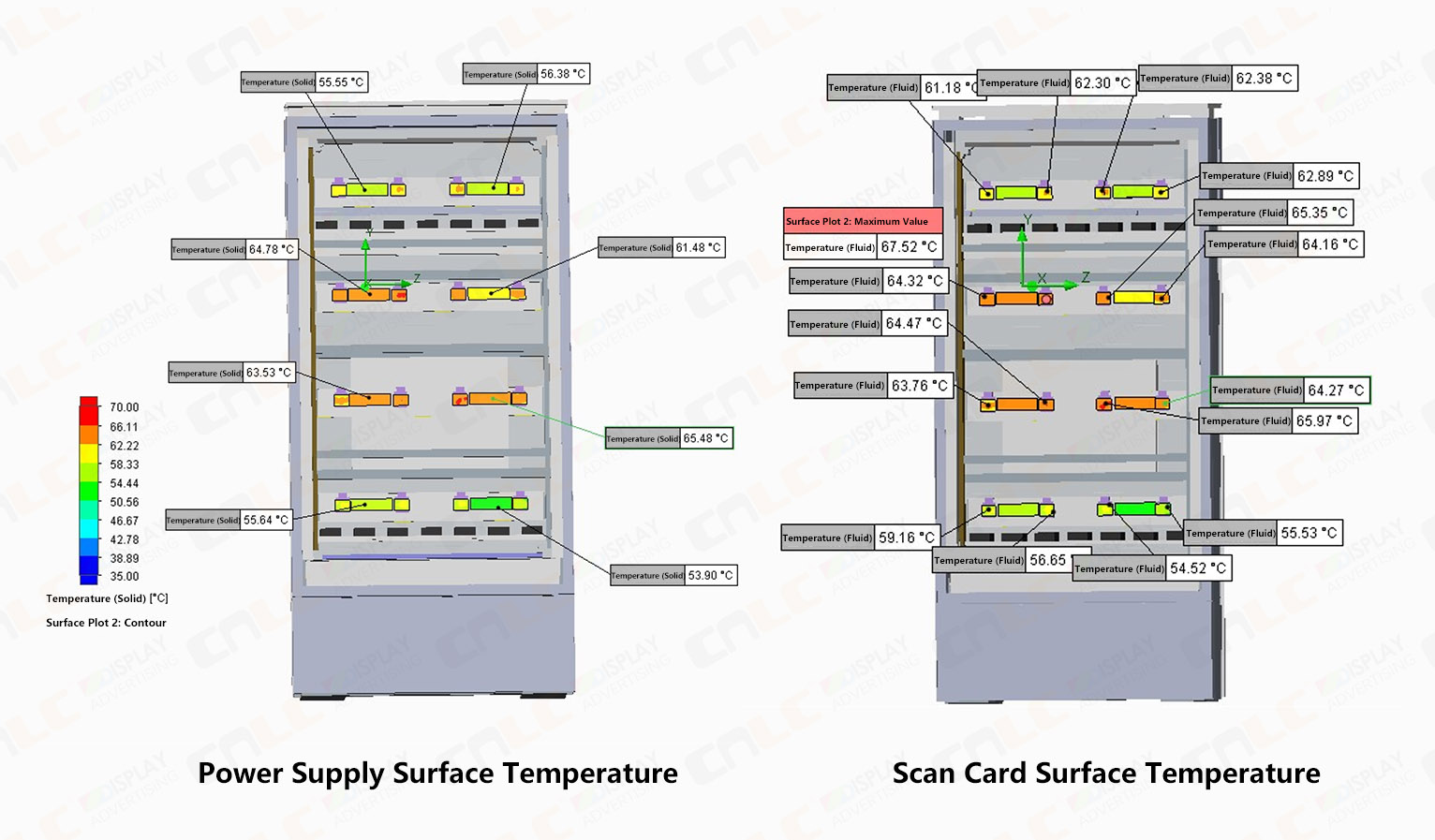

Environmental Adaptability

Outdoor combiners for macro sites should meet IP65/IP67 protection standards, while indoor DAS combiners must be compact and easy to install.

Application Cases

-

Case 1: Multi-band Combining in Macro Sites

In a metropolitan area deployment, an operator used a low-PIM tri-band combiner (700/1800/2600 MHz) to achieve three-band shared antenna deployment. This reduced feeder count by 40% and construction cost by 25%. -

Case 2: DAS in Metro Systems

In a subway coverage project, a four-way combiner was deployed to merge signals from three operators into a shared DAS. This reduced feeder cabling by 50% and significantly improved system reliability.