When designing and manufacturing electronic products, one of the key components that must be chosen carefully is the oscillator. Oscillators are crucial for providing a stable frequency source for timing, synchronization, and signal processing. Selecting the right type of oscillator can significantly impact the performance, reliability, and longevity of your product.

Understanding Oscillators

At their core, oscillators are electronic circuits that generate a periodic signal, typically a sine or square wave. In electronics, they are widely used in applications such as communication systems, clocks, signal generators, and microprocessor timing. The stability and accuracy of the oscillator's frequency are critical in ensuring the proper operation of your device, especially in environments where temperature fluctuations, power supply variations, or other external factors can affect performance.

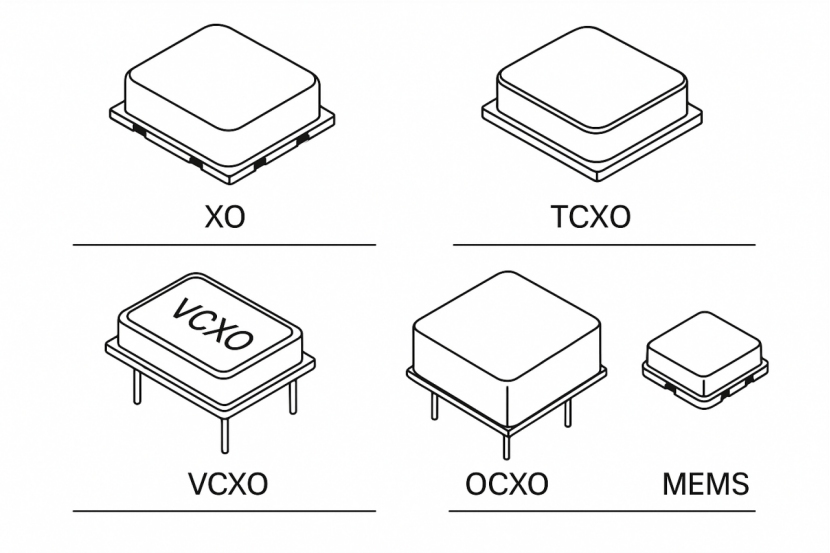

Types of Oscillators and Their Features

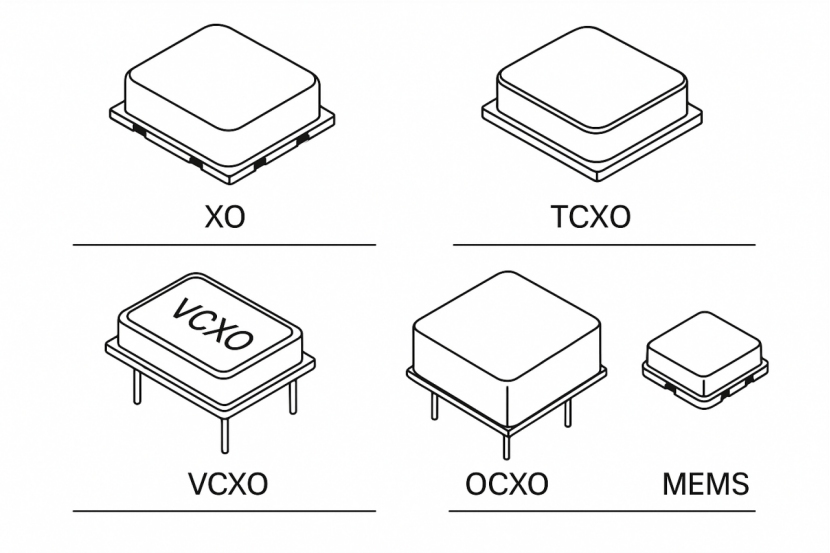

XO (Crystal Oscillator)

A Crystal Oscillator (XO) is a fundamental frequency source used in most electronic systems. The frequency of a standard XO is determined by the physical properties of the quartz crystal. These oscillators offer good accuracy and stability under normal operating conditions.

Pros:

Low cost and simple design

Suitable for a wide range of applications

Stable in typical operating environments

Cons:

Limited temperature stability (frequency may drift with temperature changes)

Accuracy may not be sufficient for highly demanding applications

For applications where low cost and general performance are adequate, a Crystal Oscillator from Shenzhen Jingguanghua Electronics Co., Ltd. might be a suitable choice, offering reliable performance in everyday products.

TCXO (Temperature Compensated Crystal Oscillator)

A Temperature Compensated Crystal Oscillator (TCXO) offers enhanced temperature stability. It uses a built-in circuit that compensates for temperature-induced frequency variations, making it more suitable for environments with significant temperature fluctuations.

Pros:

Superior temperature stability

Higher accuracy than standard XO

Ideal for portable devices or those exposed to varying environmental conditions

Cons:

Higher cost compared to XO

Slightly more complex design

If you require higher accuracy and temperature stability for applications such as GPS systems or portable communication devices, a TCXO could be a better option to ensure consistent performance across a wide temperature range.

VCXO (Voltage Controlled Crystal Oscillator)

A Voltage Controlled Crystal Oscillator (VCXO) is similar to an XO, but it allows the output frequency to be adjusted by an external voltage input. This makes VCXOs ideal for applications requiring fine-tuned frequency adjustments, such as phase-locked loops (PLLs) in communication systems.

Pros:

Adjustable frequency output

Ideal for frequency modulation applications

Excellent for use in systems that require precise frequency control

Cons:

More expensive than standard XO

Requires external circuitry to control the voltage

For applications where precise frequency control is critical, such as telecommunications equipment or high-performance computing systems, a VCXO provides flexibility without sacrificing stability.

OCXO (Oven Controlled Crystal Oscillator)

An Oven Controlled Crystal Oscillator (OCXO) is a type of high-precision oscillator that uses a temperature-controlled environment (oven) to maintain the quartz crystal at a stable temperature. This eliminates temperature-induced frequency drift, making OCXOs the most accurate and stable type of oscillator.

Pros:

Extremely high accuracy and stability

Ideal for high-performance, mission-critical applications

Excellent for use in scientific instrumentation and telecommunications

Cons:

Expensive

Larger size and higher power consumption

For applications requiring ultra-high accuracy, such as scientific research, precision measurement, and satellite communication systems, an OCXO offers unparalleled performance.

MEMS Oscillators

Microelectromechanical Systems (MEMS) oscillators are a newer type of oscillator that uses tiny mechanical structures integrated with semiconductor technologies. MEMS oscillators offer several advantages over traditional crystal-based oscillators, including smaller size, lower power consumption, and better shock resistance.

Pros:

Small form factor

Low power consumption

Highly resistant to mechanical shock and vibration

Cons:

Lower frequency stability compared to crystal-based oscillators

Potentially less accurate in demanding applications

MEMS oscillators are ideal for portable devices and wearables, where space and power consumption are critical, while still offering reliable performance in less demanding environments.

Choosing the Right Oscillator for Your Application

When selecting an oscillator for your product, it is important to consider several factors:

Temperature Range: If your product will be exposed to varying environmental conditions, choose an oscillator with a high-temperature stability, such as a TCXO or OCXO.

Accuracy Requirements: For applications requiring precise timing or synchronization, a VCXO or OCXO is recommended.

Size and Power Constraints: If your device needs to be compact and power-efficient, consider a MEMS oscillator.

Cost Considerations: If cost is a major factor, an XO or TCXO might be more suitable, as they provide a balance of performance and affordability.

Choosing the right oscillator for your electronic product is crucial to ensuring reliable operation and maintaining performance in varying conditions. Whether you need the high accuracy of an OCXO, the temperature stability of a TCXO, or the compactness of a MEMS oscillator, understanding the specific requirements of your application will help you make an informed decision. Always consider factors like environmental conditions, power consumption, and required frequency stability to select the most suitable oscillator type.

For more information on choosing the right crystal oscillator for your next project, please feel free to contact Shenzhen Jingguanghua Electronics Co., Ltd. We specialize in providing high-quality, reliable oscillator solutions.